Industrial Part De Rusting and Rust Removal Services for Manufacturing Applications.

West Michigan Ultrasonic offers industrial rust removal services to companies of all sizes. We have saved manufacturing companies tens of thousands of dollars by derusting machined steel parts, cast parts, blind holes, cavities and more. Our rust removal process only removes rust from the parts. The part tolerances and exposed material will not be changed in any way. We apply rust inhibitors based on customers specifications to protect against future rust formation. This rust removal process uses no hazardous acids and does not leave a crystallized coating on the parts.

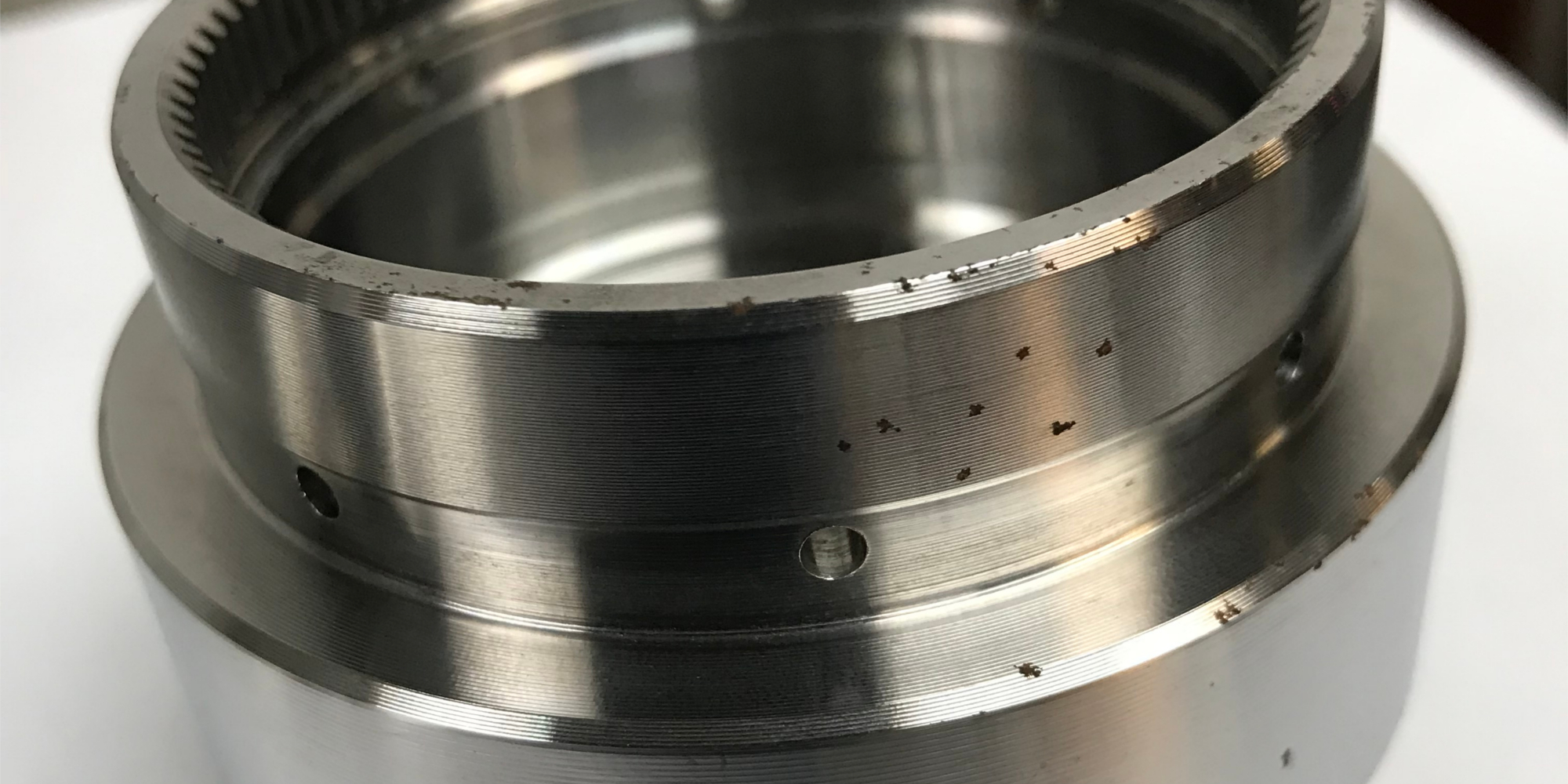

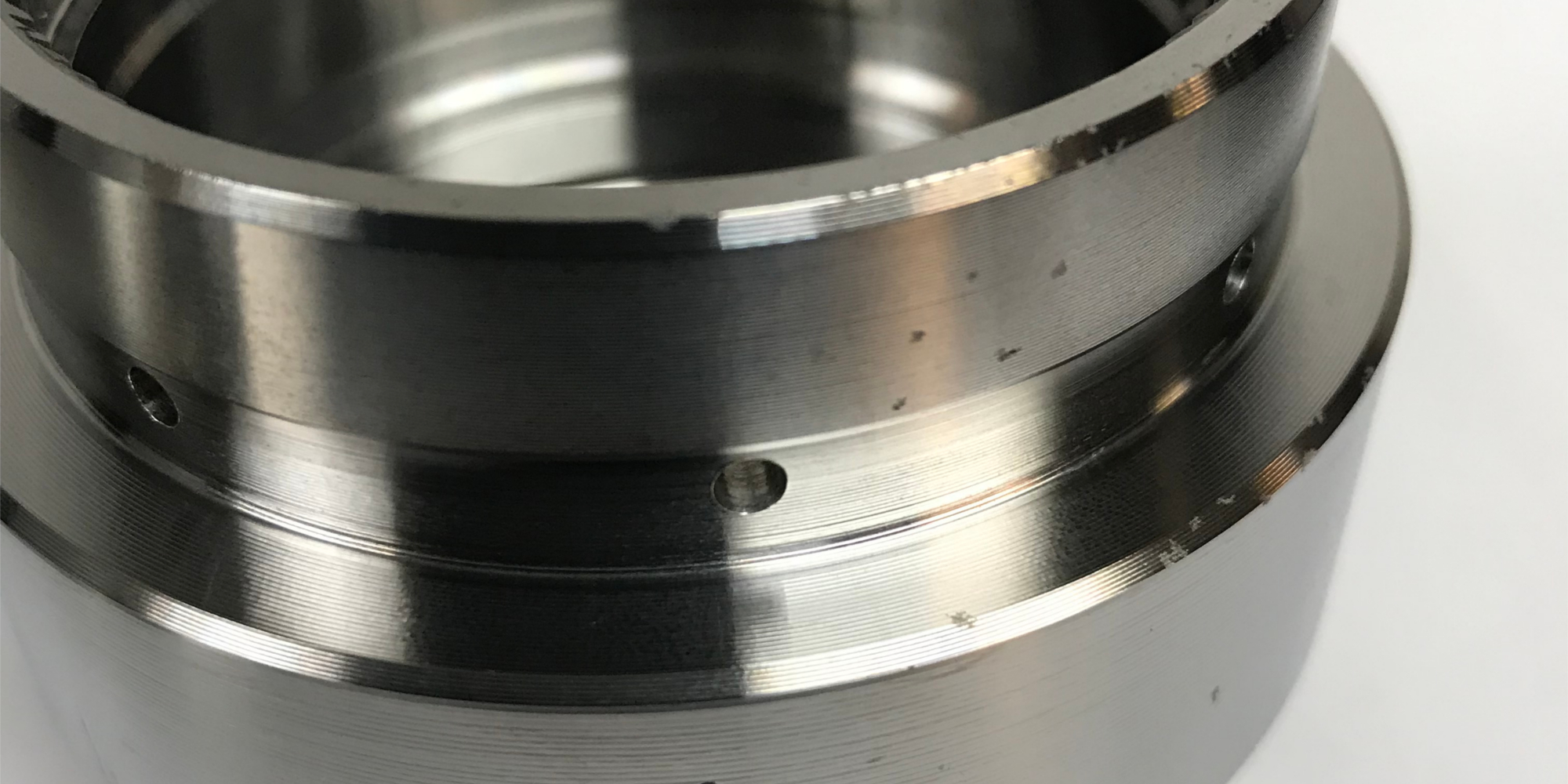

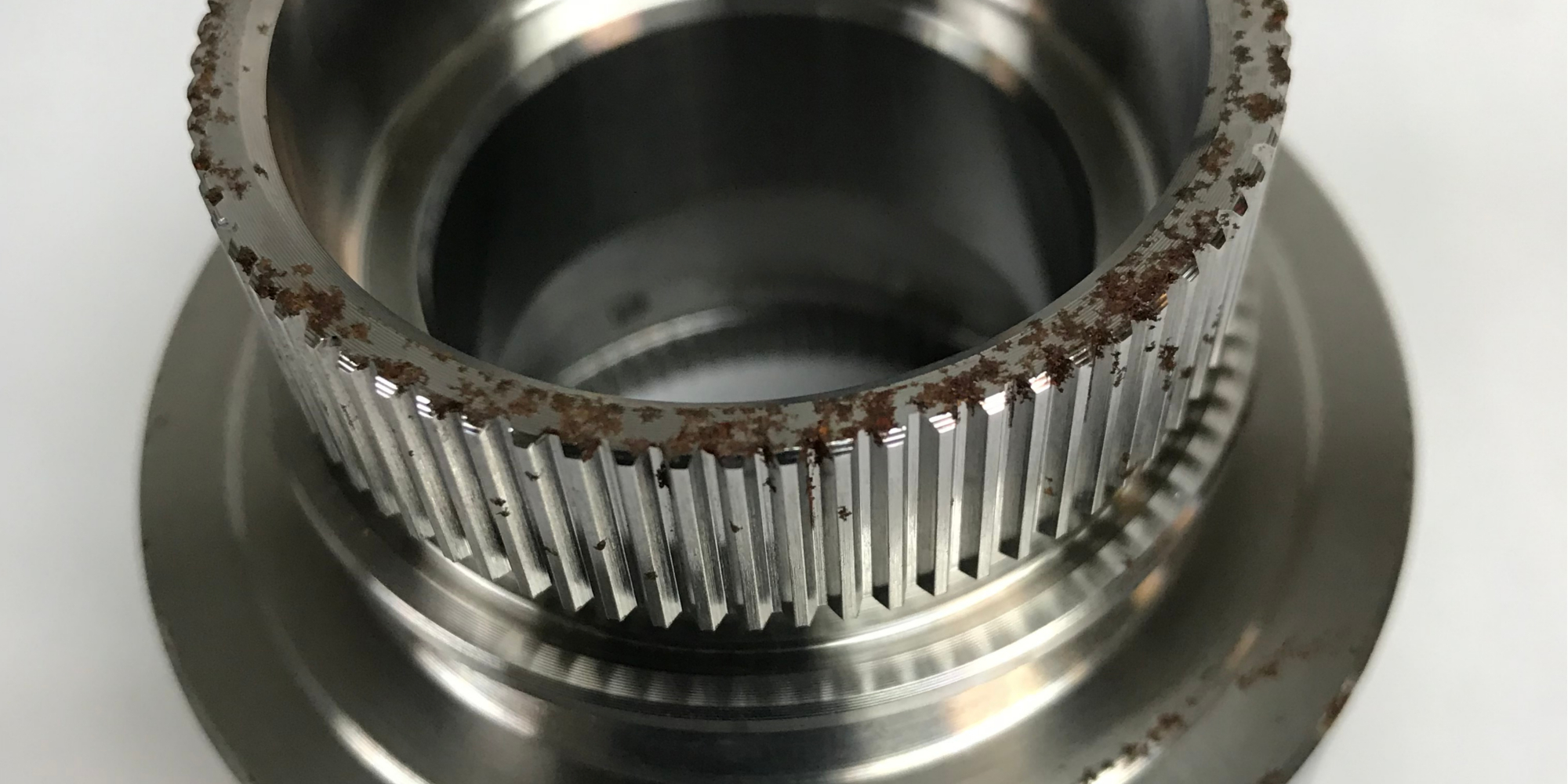

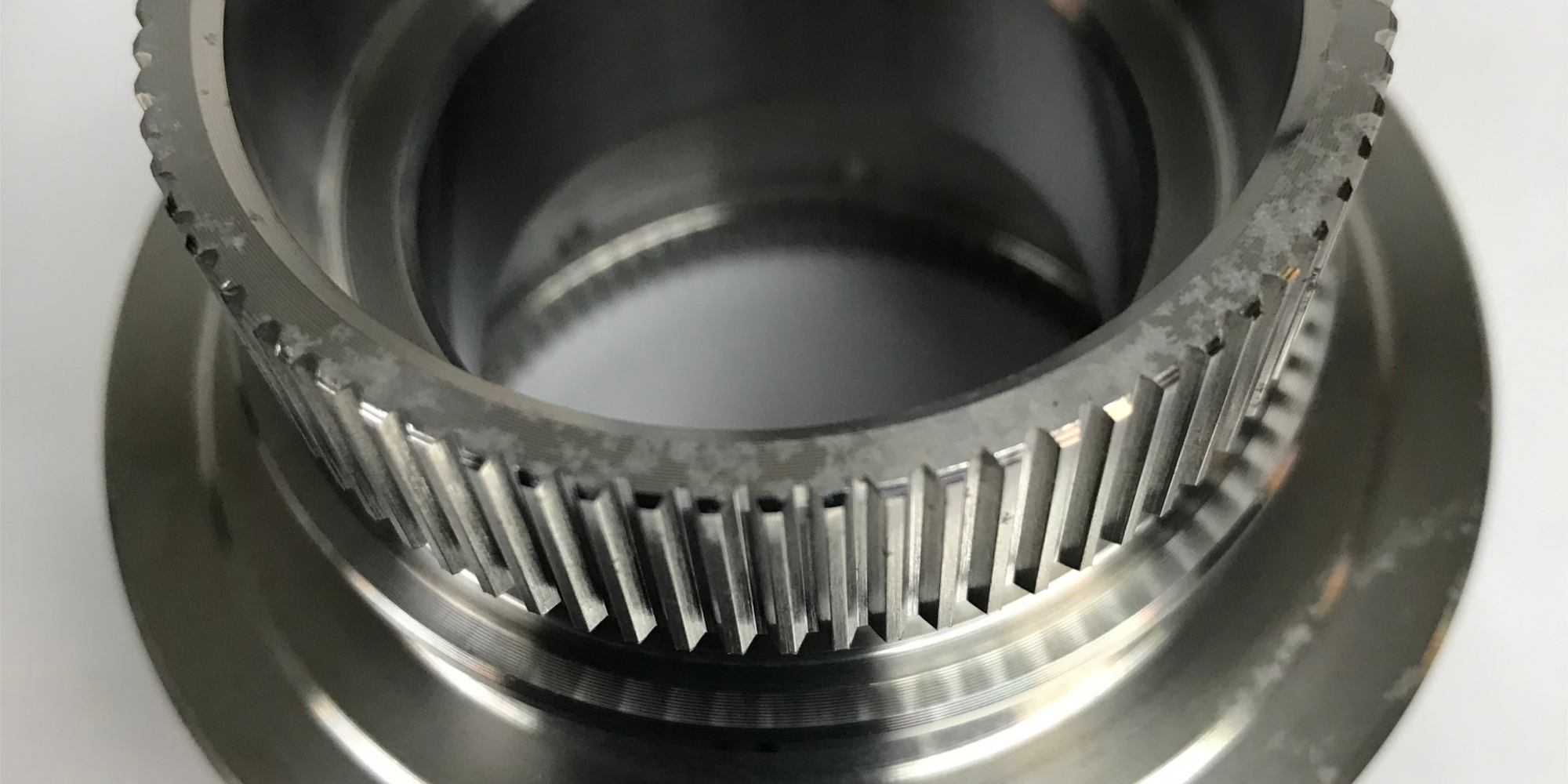

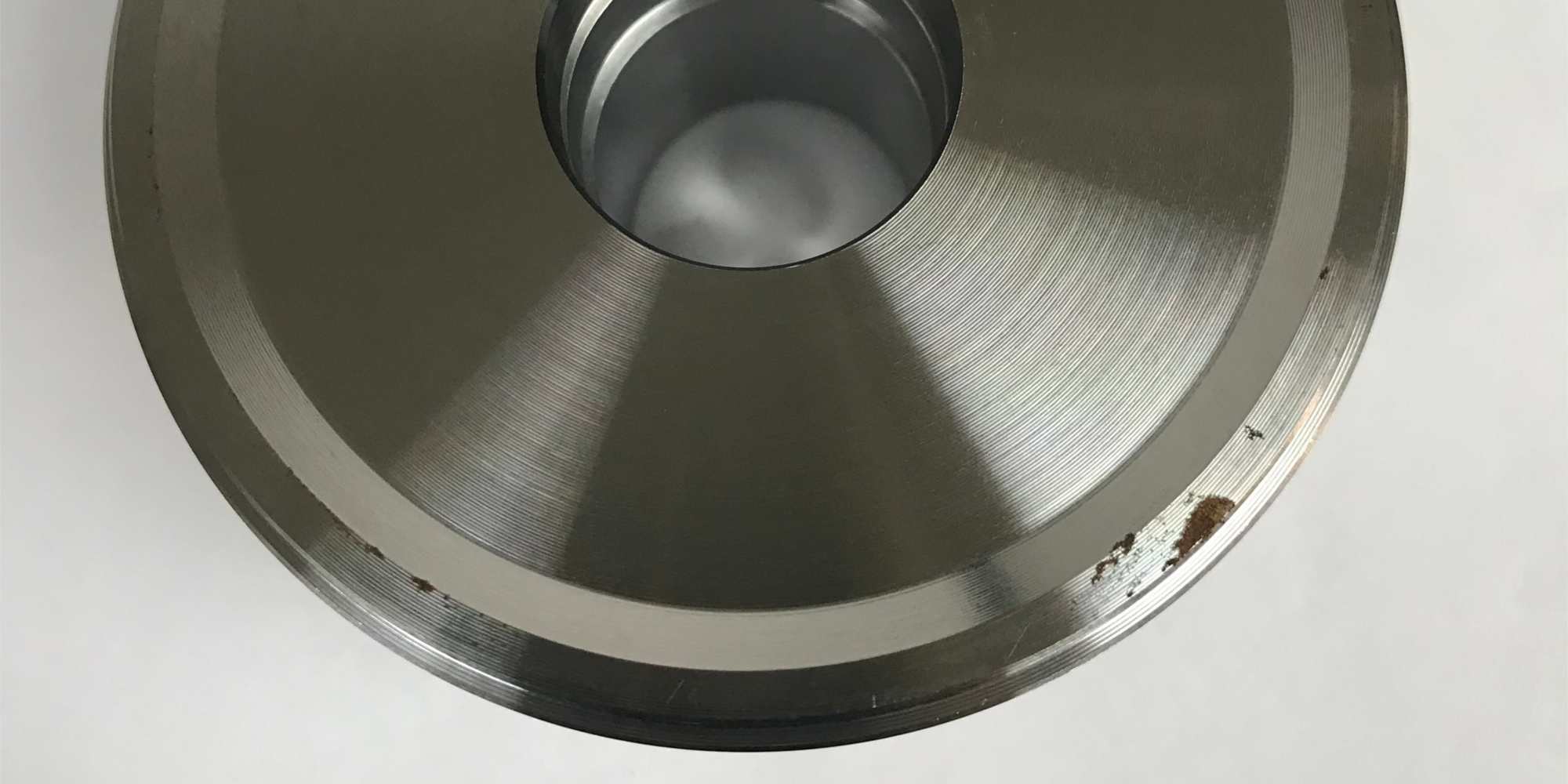

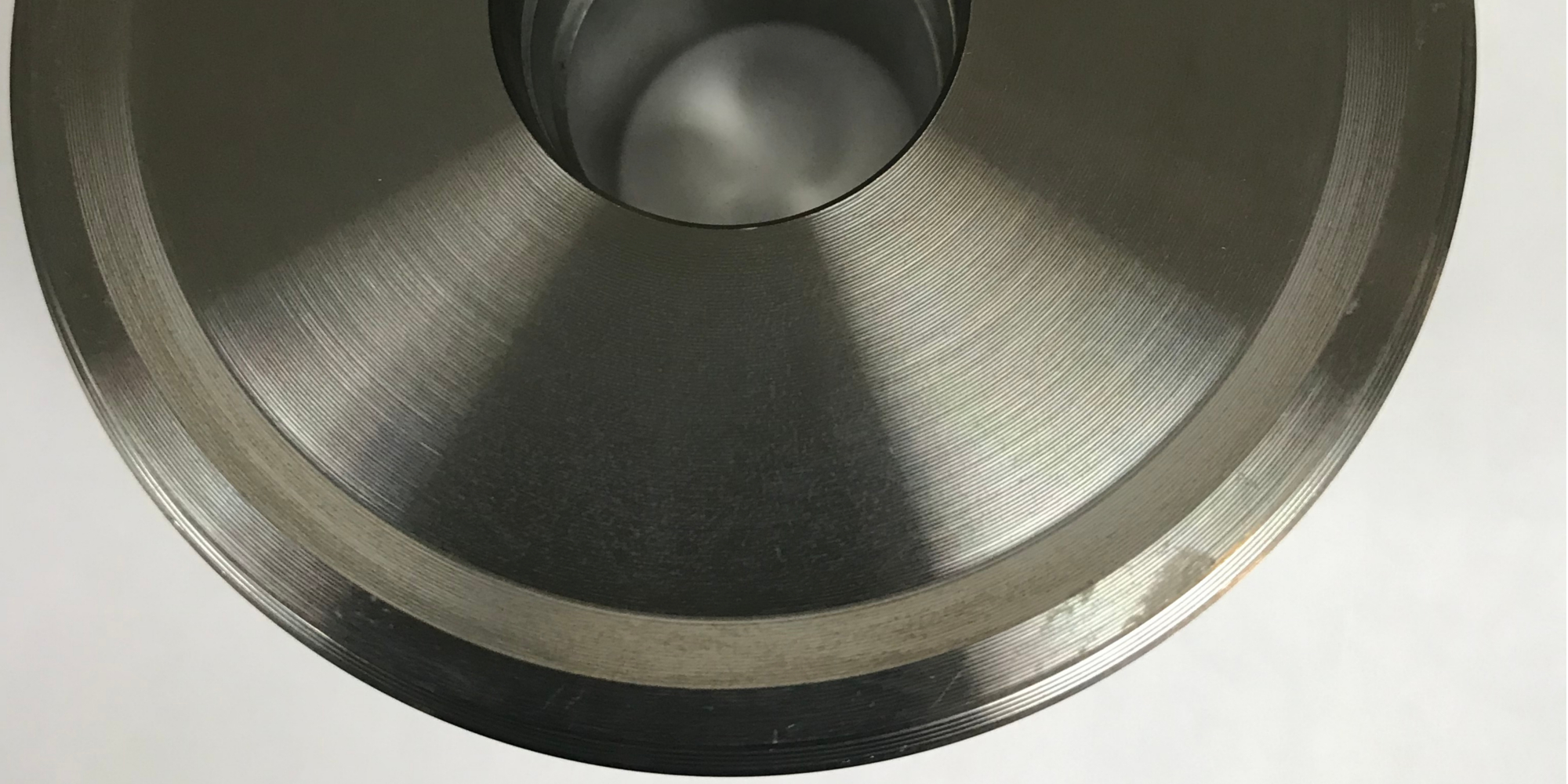

Our equipment can de rust high volumes of parts allowing for fast turn around times. Our rust removal process, for steel parts, uses specially formulated cleaning chemicals developed in the USA and safe for the environment. We package according to manufacturer dunnage requirements. Below is an example of a machined transmission part for the automotive industry.

Manufacturing Part De Rusting and Rust Removal Services: Automotive, Aeronautics, High Performance, Part Reconditioning.

Motorcycle Exhaust Rust Removal Results.

High Volume Rust Removal Services available at West Michigan Ultrasonic.

Our Ultrasonic Cleaning Equipment is large enough to provide fast turn around times for large jobs. Pictured to the right is a pallet of rusted transmission parts. The parts dunnage had rust embedded into the plastic. We also developed a ultrasonic cleaning process to remove the rust and clean the parts trays before packaging parts and returning to client. Give us a call for more information. 616-822-6962

Get an Ultrasonic Rust Removal Quote Today!

Fill out our easy “CLEAN IT” Email Form and receive a quote today.

Rust Removal from Manufactured Cast Steel Parts.

Cast Steel porous part surfaces are rough and hold contaminants very well. This type of surface is especially difficult to remove rust and properly clean for Rust Protectant application.

We use a Heated Immersion Tank to apply Rust Protectant per customers specifications.

Our rust removal process thoroughly cleans parts before Rust Protection is applied. Also, we specify the Rust Inhibitor based on manufacturer requirements. This flexibility separates us from other rust removal services. In order to have any Rust Protectant perform properly, the parts must be dry and contaminate free before application. Our Ultrasonic Cleaning process removes rust, debris and contaminants from all surfaces of the parts, even blind hole surfaces and/or inner spline surfaces.